Description

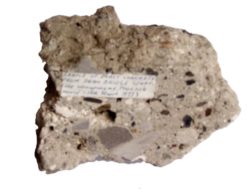

Sample of colloidal concrete of 1878 removed from a road at West Arthur Place, Edinburgh in 1972.

Used for urban road construction. Edinburgh’s City Roads Surveyor DC Proudfoot was at the forefront nationally of this type of construction and was responsible for constructing some 5 miles of cement-grouted whin stone aggregate roads in the city.

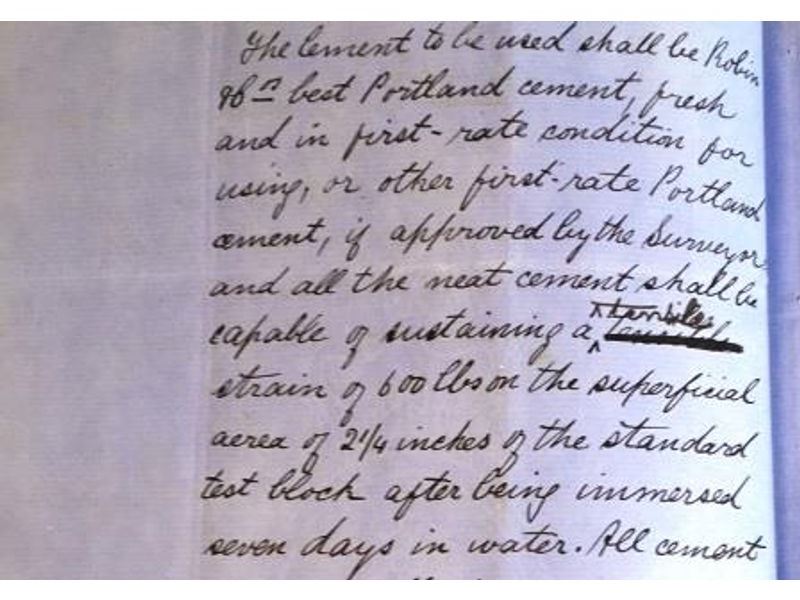

The concrete was formed on a blinded and rolled stone bottoming 6 in thick as follows: a 4.5 in thick layer of 1.5 in whin road metal was spread uniformly over the bottoming and grouted with a mixture of fine gravel riddled out of Fisherrow gravel and Robin & Co’s best (Portland Cement). The cement used was to be capable of sustaining a tensile strain of 600 lb on the superficial area of 2.25 in of the standard test block after being immersed 7 days in water. The grout was mixed in a patent steam mixing machine and then spread beaten and “equalised” into the road surface “in a most careful and tradesmanlike manner” (from specification). The full specification can be viewed here https://ice-museum-scotland.hw.ac.uk/wp-content/uploads/1973_033_specification_text.pdf.

A photograph of a similar concrete road surface on High School Yards, Edinburgh is shown as Image 3 (Note 1 shilling coin in centre).

This item was displayed prior to acquisition at the Institution of Municipal Engineers Centennial Exhibition, Brighton, June 1972. (Ref: DINNIS F.R.. A Catologue of the Exhibit Early Uses of Concrete in Edinburgh Roads which includes a selection of Surveying Instruments and an Ediograph in use c. 1872. The Institution of Municipal Engineers, 1972). A copy of this reference is held by the museum.

For a paper on concrete roads in Edinburgh see Paxton, RA. Early Concrete Roads in Edinburgh. Concrete UK: 11(9): 20-22, September 1977.