Description

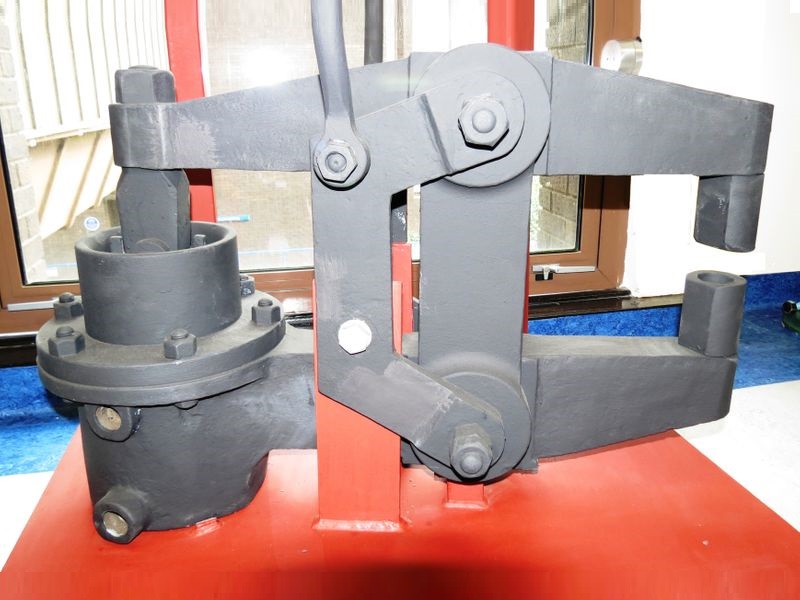

Hydraulic riveting machine designed by William Arrol for use during the construction of the Forth Bridge (c.1887).

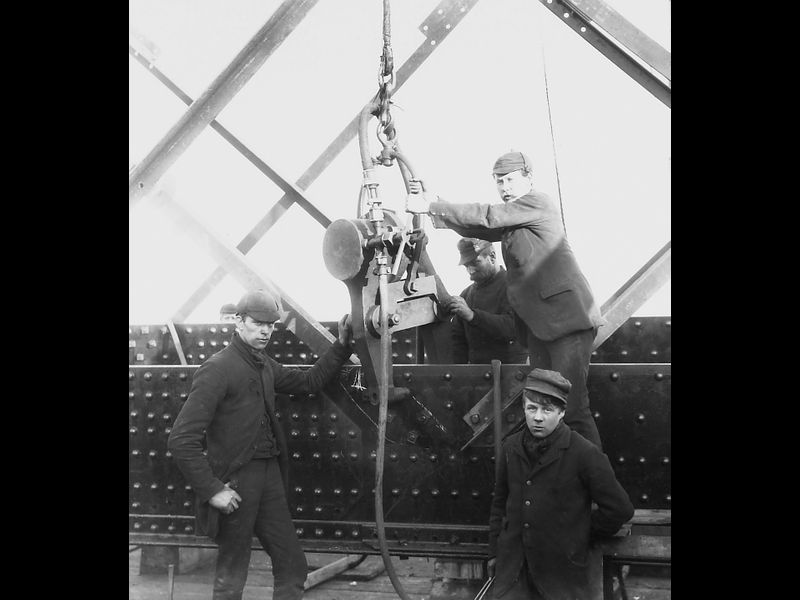

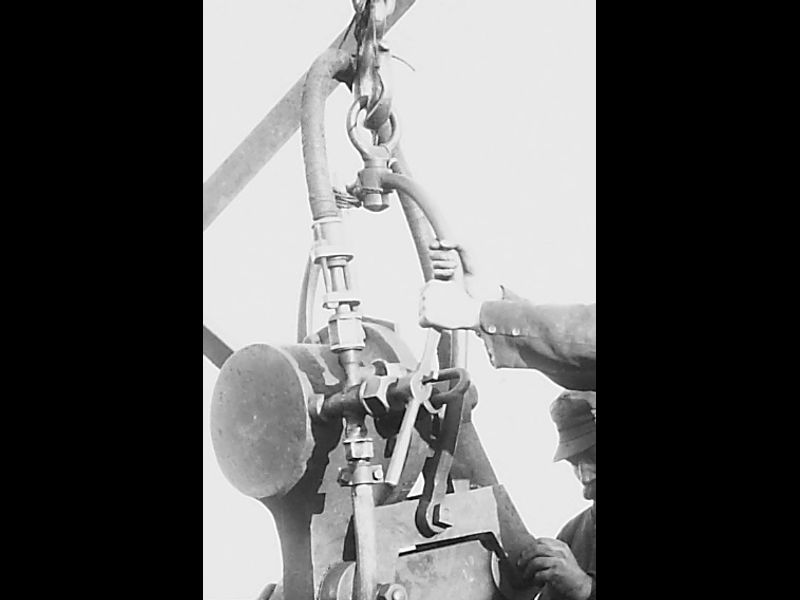

Much of the equipment (including cranes and riveting machines) used on the bridge was operated by hydraulics. The water was compressed up to a maximum of 3 tons/sq in by means of a multiplier and piped up the towers and along the cantilevers to the piece of equipment. The pipework for this had to be extended and adjusted daily as the bridge progressed. In constructing the bridge two forms of accumulator were used to store the high pressure water. As there was no electricity, one comprised a 16 in cylinder loaded by dead weight and the other an 8 in cylinder loaded by steam.

The hydraulic riveting machines were specially designed by the Arrol firm. Arrol is believed to have described the advantages of this tool as follows: “The Hydraulic Riveter doesn’t turn up for work late; its hands don’t shake from excess drink and they don’t strike for more pay.”

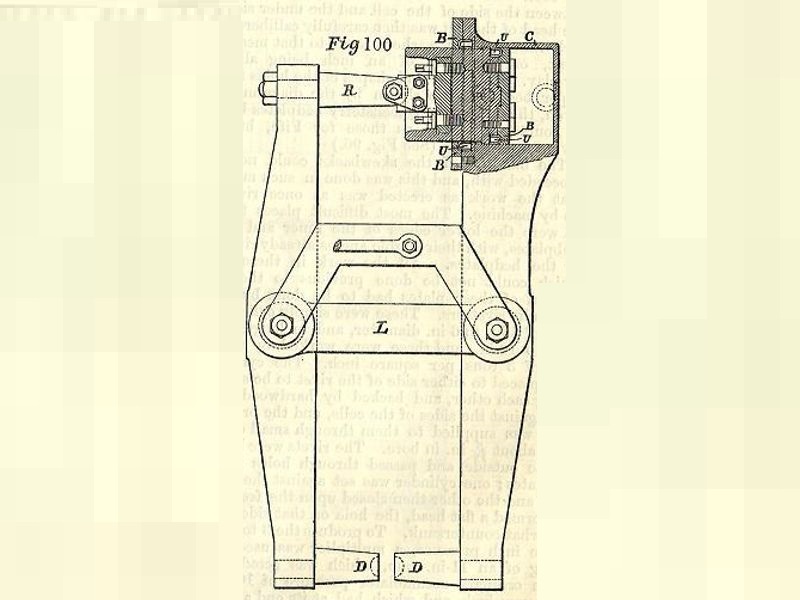

The riveter displayed represents a “jointed” machine rather than a “fixed” machine. A jointed machine is based on a double lever arrangement at the end of the two arms. These are opened and closed by applying the hydraulic pressure at the other end of the arms to form the rivet head. The rivets were heated in a small oil furnace to a yellow heat. As soon as a rivet was put into place both of its ends were located in the dollies, pressure applied and the rivet was closed.

The jointed riveting machines were designed to be suspended from a crane for use either vertically or horizontally. Flexible hydraulic hoses were used to convey the pressurised water. It depended entirely upon the places where rivets had to be struck whether a jointed or fixed machine was used. The fixed machine was surer in its action because the double lever arrangement of the jointed machine was apt to twist, and thereby bending the unclosed portion of the rivet before it was properly formed. Of course, the longer the arms the greater became this tendency, and as some of the jointed machines had to be used with the arms fully 4 ft 6 in in length, great care had to be exercised. (WESTHOFEN, W. The Forth Bridge. Engineering, London, 1890.)

An example of a rivet of the type closed by this machine is in the collection and can be seen at here.

This item is on loan from the National Railway Museum, York.