Description

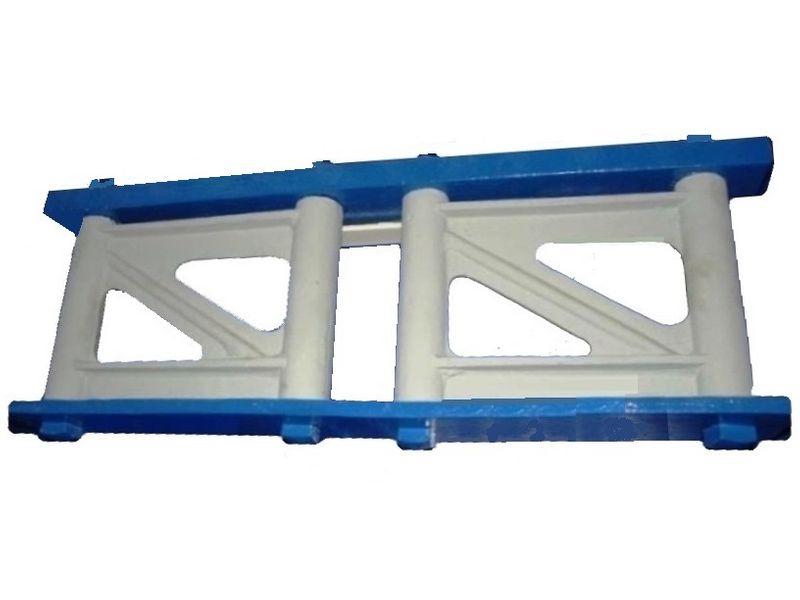

Section of a McConnel Patent Cast-Iron Composite Beam (c.1864).

Precursor of the modern I-beam – a McConnel beam with cast-iron web and malleable iron flanges. Of a type patented by Robert McConnel in Glasgow in 1855. Installed in a building erected in 1864 at 24-30 Jamaica Street, Glasgow, for G & J Burns, founders of the Cunard Shipping Line. Architect, John Honeyman. The building was demolished in 2000.

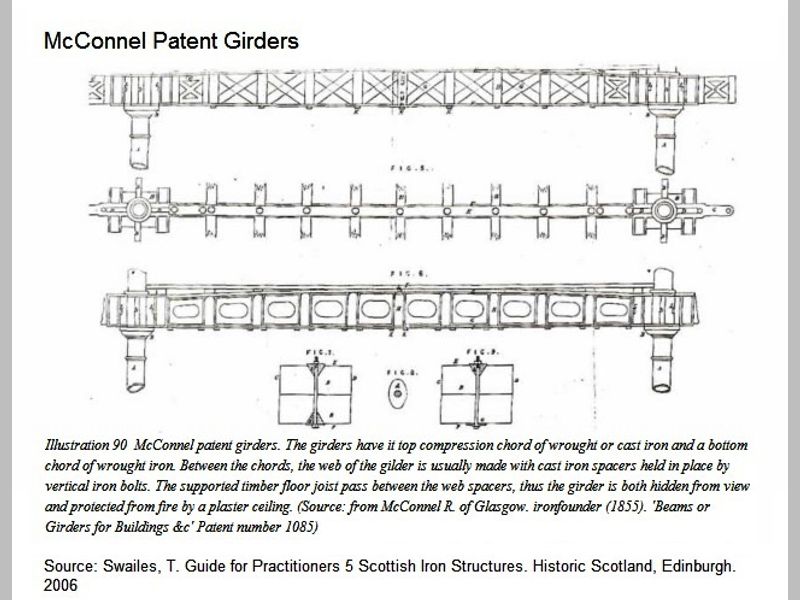

Tom Swailes writes:

By the mid-I850s, distrust of cast iron beams in building floors was fairly widespread after several building collapses. At a meeting of the Architectural Institute in Edinburgh in 1856, Thomas Davies gave details of proof-tests made for him on a variety of wrought iron girders made up of riveted angles and boiler plate. The tests had been carried out in the yard of an engineering works in Leith Walk owned by Mr Tod. Davies reported that Mr. Tod ‘subsequently made many such beams for other parties, so that they have to some extent become known and used in this locality’.

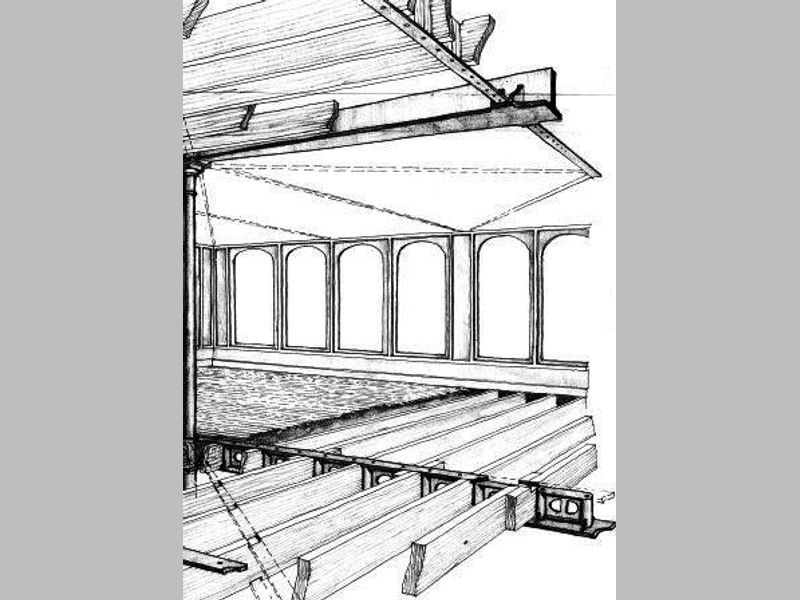

In 1855, Robert McConnel patented a novel form of iron floor beam that was used in a significant number of Glasgow buildings. The floor to the great hall in Rutherglen Town Hall, constructed in 1862 to the design of architect Charles Wilson, used McConnel patent girders of 34′ clear span to support timber joists spanning 10′. Professor W J M Rankine of Glasgow University was consulted about the strength of the floor while the building was under construction. Taking crowd loading as 120 lbs/ft2 (5.75 kN/m2) with another 30 lbs/ft2 (1.44 kN/m2) for the weight of the floor, Rankine concluded from his structural calculations that the McConnel girders were far too weak. The Town Council resolved to prop the McConnel girders at mid-span by an additional cast iron girder supported on cast iron columns. The use of a cast iron girder was not in accordance with Rankine’s advice, which had been to use a girder of malleable iron (i.e. wrought iron).

Wrought iron beams and girders were lighter than the equivalent in cast iron and, as its use in buildings increased, wrought iron gained the advantage in terms of cost too. In 1884 a London engineering contractor compared a wrought iron plate girder (with a ⅛” x 15″ deep plate web and 3″ x 3″ x ⅜” riveted angle flanges), with the equivalent cast iron beam. The wrought iron section weighed 44 lbs/ft (65 kg/m) and cost 11 shillings per cwt, compared to 133 lbs/ft (198 kg/m) and 7 shillings per cwt for the cast iron. From around this time cast iron beams and girders tended to be used mainly in situations where durability was required, such as lintels and in ground floors over basements.

(Ref: Swailes, T. Guide for Practitioners 5 Scottish Iron Structures. Historic Scotland, Edinburgh. 2006.)